Production Services

Services

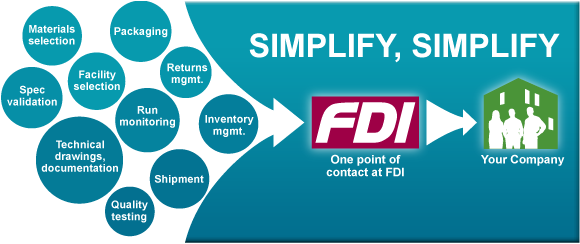

Tap the ideal supply chain with one point of contact

- Prototypes

- Specialty runs

- High volume

- 100% quality guaranteed

Our experts save you time, money, and hassle

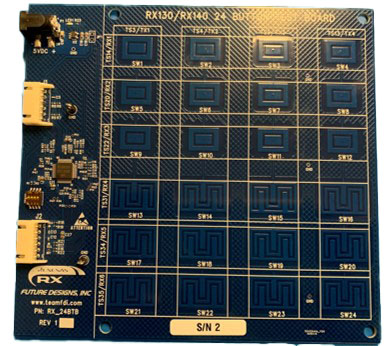

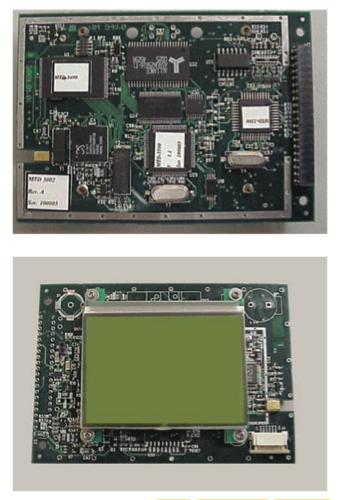

From single prototypes to high volume production, FDI can build and deliver your product to you or your end user. We have in-house production capabilities for quick turnaround on prototypes and small volume runs. We also have strong relationships with contract equipment manufacturers for large volume projects, and can coordinate directly with any manufacturer you prefer.

Simplify production

With FDI managing the manufacturing, you can move to the next project. It’s like having your own production department, but only when you need it.

Hassle-free

We manage all of the details concerning component availability, manufacturing schedules, functional test issues and quality. We ensure a smooth manufacturing flow so you can focus on other critical aspects of your product introduction.

Meet the bottom line

Our strong relationships with suppliers and comprehensive experience with the manufacturing and component supply chain gives you a lower total cost of ownership (TCO) than if you spent valuable time dealing directly with contract equipment manufacturers.

100% satisfaction

Whether we build your product in house or at one of our CEMs, we monitor production for quality and reliability. We provide a complete customer documentation package that includes full technical drawings, BOMs, schematics, PCB Gerbers, and product specifications.

How it Works

The links provide examples of the respective capabilities.

- FDI appoints a single production manager who stays with you throughout the design and production stages.

- FDI validates the final specs and design for production, recommending any changes that may save on material costs or production and testing time.

- FDI works with vendors to identify the optimal materials for the job and selects the facility best suited to the run.

- FDI develops full technical drawings, final schematics, PCB Gerber files, and bill of materials (BOM).

- FDI develops testing procedures and any necessary functional test system.

- FDI monitors the production run.

- FDI inspects every component and product on two levels.

- FDI ships directly to you or your customer.

- FDI can stock inventory at prearranged levels.

- You get your product to market fast, with no hassles, enabling you to concentrate on what you do best.

Quality & Testing

FDI offers a 100% quality guarantee. If a device does not work on arrival, you don’t pay for it.

We believe that high quality production translates into profits for us and our clients. To back up our guarantee, we develop functional testing and inspect devices on–site. We provide these two levels of quality control with no added cost to our clients.

FDI products are REACH and RoHS Compliant

Industry standards are an important part of how FDI measures the quality and safety of our products. We ensure all products are REACH and RoHS Compliant.

- FDI RoHS Product Declaration

- FDI REACH Directive

- FDI Mercury Certificate

- FDI Conflict Minerals Reporting Template (CMRT)

Design for quality

Our quality control starts at the design stage, where our engineers design for manufacturability (DFM) and design for test (DFT). This design stage is critical for on-line success. When manufacturing products designed by our customers, we verify the designs with DFM and DFT analysis.

Incoming testing

FDI offers to supply automated functional test stations to our customers to correlate incoming product quality.

On-line testing

Before the first unit comes off the line, FDI engineers will design and develop automated functional test systems customized for the unit. The units are inspected for cosmetic, structural, and functional defects. Functional circuit testing (FCT), integrated circuit testing (ICT) and VI testing is fully supported.

Continual analysis

We continually analyze our quality control data and share with our customers to continually improve the quality of each product.

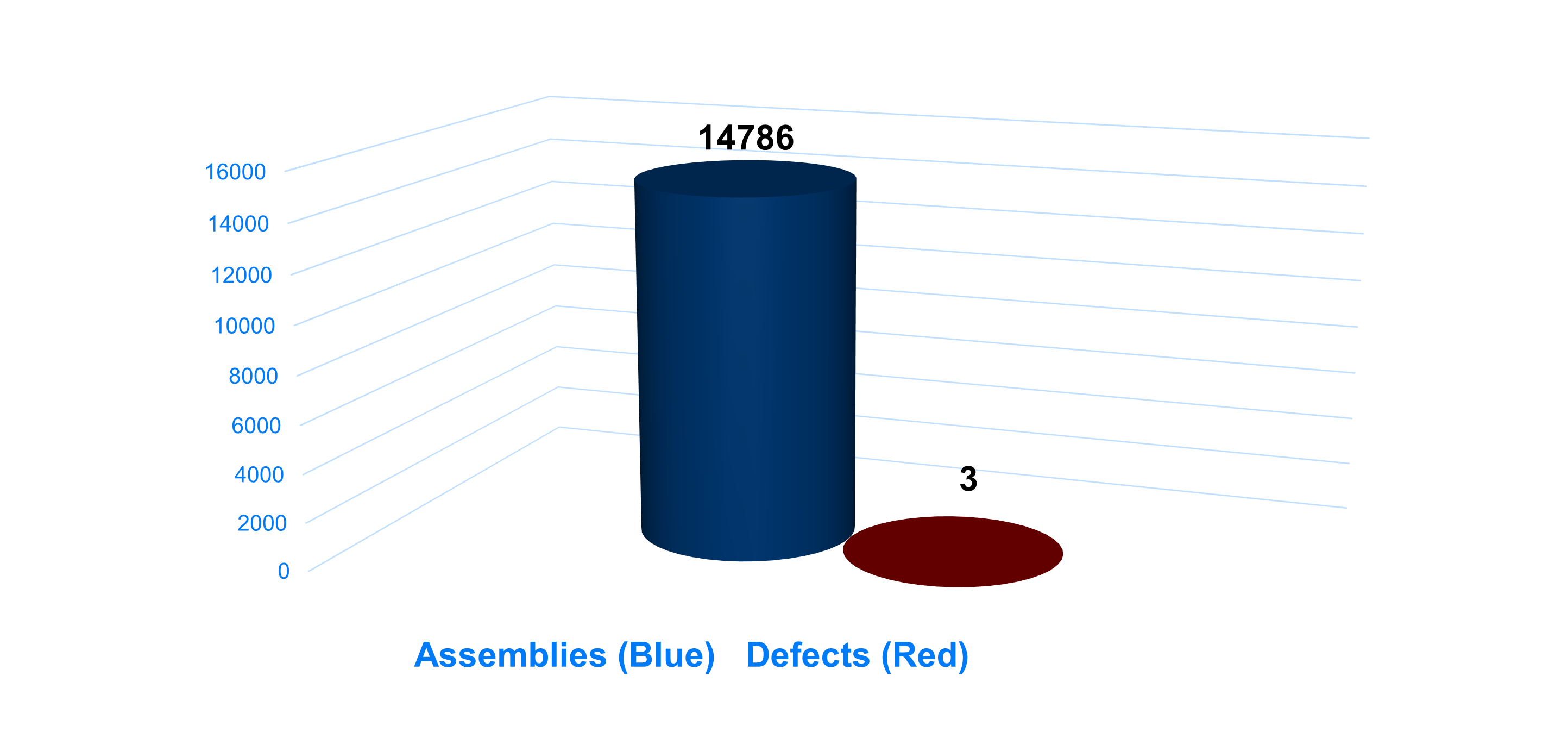

Defects for Customer A in 2024

To illustrate the quality of our builds at FDI, lets show an summary of the defects for a customer (A) during 2024. With 14,786 units built, only 3 defects were reported.